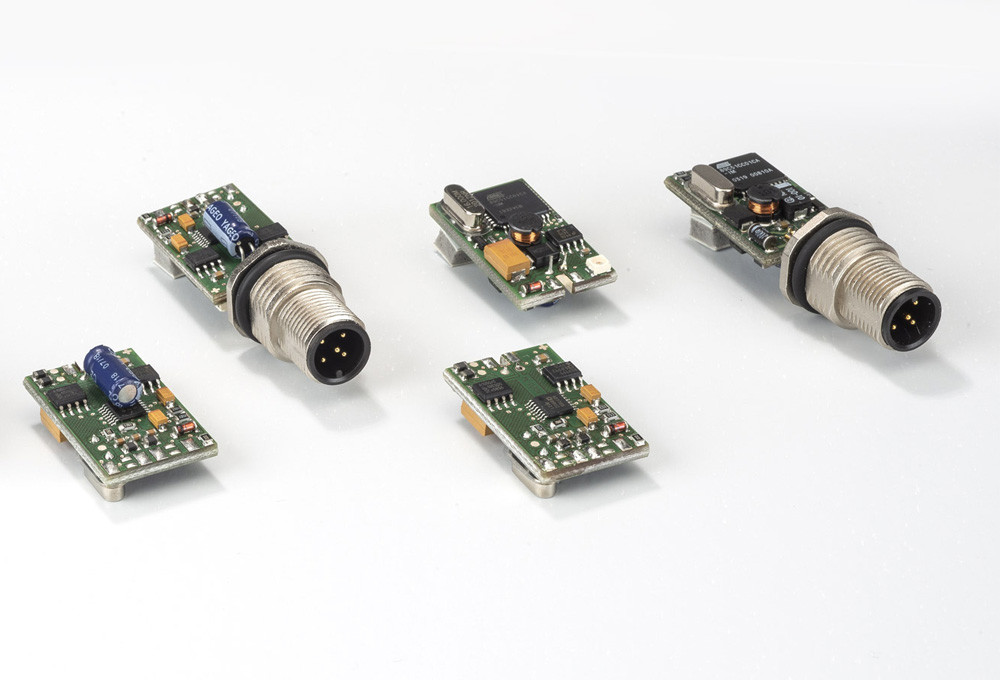

I/O Modules

Introduction to the industrial application of I/O modules

I/O modules are a fundamental component in industrial automation. They act as an interface between the control unit and the operational devices of the production line, facilitating precise control of complex processes.

Our products have a CAN interface, so we support the CANopen, CANopen FD and J1939 protocols.

Box

Snap

With its standard 19″ casings the µLAB product family is ideally suited for a wide range of industrial and experimental research and testing tasks and offers …

F1

TRS

Basics of I/O modules in industrial applications

I/O modules (input/output modules) are key components for monitoring and control of industrial machines and systems. They are designed to reliably transmit and receive signals which is essential for efficiency and safety in production environments.

Kinds of I/O modules

Industrial I/O modules can be divided into two main categories: digital and analogue modules. Digital modules are used to process simple signals such as on/off states, while analogue modules measure complex signals such as temperature or pressure.

Selection criteria for industrial applications

Selecting the right I/O module for industrial applications requires a deep understanding of the specific requirements of the production process, including environmental conditions, required accuracy and system integration.

Technical aspects and configuration of I/O modules

Modern I/O modules for industrial applicatons are highly developed and can be used in a wide range of configurations. Their flexibility allows them to be adapted to a variety of different production requirements.

Network protocols and connectivity

Industrial I/O modules work with various network protocols such as CANopen, CANopen FD, J1939, Ethernet/IP, PROFIBUS or MODBUS, which ensure robust and fast communication. Selecting the right protocol is crucial for integrating the modules into existing industrial networks.

Software and programming

I/O modules are configured and programmed using specialised software, so that the modules can be precisely tailored to the needs of industrial processes. Software updates ensure that the modules fulfil current safety standards and work efficiently.

Practical application examples of I/O modules in the industry

I/O modules are versatile and contribute significantly to the optimization of industrial processes.

In the automotive industry

In automotive production, I/O modules perform critical tasks such as controlling robots on production lines that perform precision work in welding and assembly. By precise control of the equipment, I/O modules help to ensure high quality of the vehicles and reduce production costs.

In the food and beverages industry

In food processing, I/O modules monitor the temperature and humidity in production facilities to ensure compliance with hygiene standards and product quality. Their ability to react in real time prevents production errors and reduces waste.

Innovative developments

The future of I/O modules in the industry looks promising, with advancements in areas such as artificial intelligence and machine learning enabling even more precise control and fault diagnosis. These technologies will help I/O modules to independently recognise malfunctions in the production process and initiate corrective measures.

Summary and conclusion

I/O modules are an essential part of industrial automation. By precisely monitoring and controlling production processes, they make a significant contribution to increasing efficiency and reducing costs. As technological progress continues, they will become even more powerful and versatile, making them an even more valuable tool in modern industry.

FAQs

What is the main advantage of I/O modules in industrial applications?

I/O modules improve communication and monitoring of industrial processes, increase efficiency and reduce errors and downtime.

How do you select the right I/O module for an industrial application?

The specific requirements of the process, such as the type of signals to be transmitted, the required data rate and the environmental conditions, are decisive factors.

What role do network protocols play in I/O modules?

Network protocols enable communication between I/O modules and the central control unit. They must be robust and reliable in order to ensure efficient data transmission.

Can the software of I/O modules be updated?

Yes, the software of I/O modules can be updated to integrate new functions or to improve the safety and efficiency of the modules.

You have further questions?

+49 2241 – 25 65 9 – 0

Write an email or give us a call.